A Precise Fabrication & Production Drawing with Industrial Codes Including BOQ

In fabrication drawings of industrial manufacturing and engineering, precision is not a luxury—it’s a necessity. At CORE DESIGN CENTER, we specialize in delivering Fabrication Drawings that are not only technically accurate but also aligned with global industrial standards and codes. Our drawings serve as the backbone of successful fabrication and production processes, ensuring seamless execution from concept to completion.

What Are Fabrication Drawings?

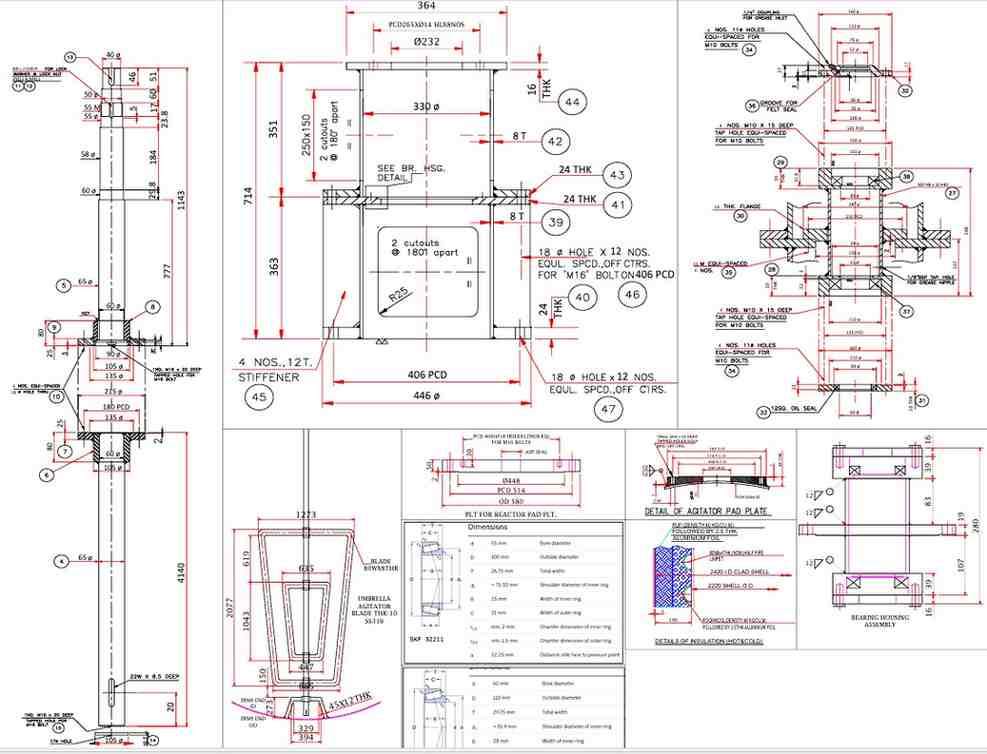

Fabrication Drawings are detailed technical illustrations used to guide the manufacturing and assembly of components, structures, and systems. These drawings include dimensions, materials, welding symbols, tolerances, and surface finishes. They are essential for fabricators, engineers, and contractors to understand exactly how a product or structure should be built.

Unlike general arrangement drawings, fabrication Drawings dive deep into the specifics—offering a granular view of each part, joint, and connection. They eliminate ambiguity, reduce errors, and ensure that every stakeholder is on the same page.

Why Precision Matters in Fabrication Drawings

Precision in Fabrication Drawings is critical for several reasons:

- Error Reduction: Accurate drawings minimize costly mistakes during production.

- Time Efficiency: Clear instructions speed up fabrication and reduce rework.

- Compliance: Adherence to industrial codes ensures safety and regulatory approval.

- Cost Control: Detailed BOQs (Bill of Quantities) help manage budgets effectively.

At CORE DESIGN CENTER, we understand that even a millimeter of deviation can lead to structural failures or production delays. That’s why our drawings are crafted with meticulous attention to detail.

Integration of Industrial Codes and Standards

Our Fabrication Drawings are developed in strict compliance with internationally recognized codes and standards, including:

- ASME (American Society of Mechanical Engineers)

- API (American Petroleum Institute)

- ISO (International Organization for Standardization)

- IS 875 & IS 1893 (Indian Standards for structural design and seismic analysis)

By integrating these codes, we ensure that every drawing meets the highest benchmarks for safety, durability, and performance. Whether it’s a pressure vessel, storage tank, piping system, or structural frame, our drawings are engineered to withstand real-world conditions and regulatory scrutiny.

Inclusion of BOQ: Bill of Quantities

A Bill of Quantities (BOQ) is a vital component of our drawing package. It provides a comprehensive list of materials, components, and labor required for fabrication and production. Our BOQs are:

- Detailed: Every nut, bolt, and weld is accounted for.

- Quantified: Accurate measurements and quantities are provided.

- Cost-Effective: Helps clients plan budgets and control expenses.

- Linked to Drawings: Each item in the BOQ corresponds directly to the drawing for easy reference.

This integration of BOQ with Fabrication Drawings empowers clients to make informed decisions, streamline procurement, and avoid material wastage.

Applications Across Industries

Our Fabrication Drawings are trusted across a wide range of industries:

- Oil & Gas: Pressure vessels, skids, and piping layouts

- Water Treatment: Tanks, clarifiers, and structural supports

- Process Plants: Equipment foundations, ducting, and mechanical systems

- Heavy Fabrication: Steel structures, platforms, and gantries

- Building Facade: Curtain walls, glazing systems, and support frames

Each drawing is customized to suit the unique requirements of the project, ensuring optimal functionality and aesthetic appeal.

Value-Added Features

What sets CORE DESIGN CENTER apart is our commitment to innovation and client satisfaction. Our Fabrication Drawings include:

- 3D Visualization: Helps clients and fabricators understand complex assemblies.

- Isometric Views: For piping and structural clarity.

- Welding Details: Including symbols, sequences, and specifications.

- Material Specifications: Grade, finish, and sourcing recommendations.

- Revision Control: Clear tracking of changes for version management.

These features enhance communication, reduce fabrication errors, and improve overall project efficiency.

Collaboration and Support

We believe that great drawings are born from great collaboration. Our team works closely with clients, architects, engineers, and fabricators to ensure that every drawing reflects the project’s vision and technical requirements. We offer:

- Interactive Design Reviews

- Quick Turnaround Times

- On-Site Support (if required)

- Digital Delivery in Multiple Formats (DWG, PDF, etc.)

Our responsive approach ensures that clients receive drawings that are not only precise but also practical and production-ready.

Why Choose CORE DESIGN CENTER?

Choosing CORE DESIGN CENTER means choosing excellence. Our team of experienced designers and engineers brings a wealth of industry knowledge and technical expertise to every project. We are committed to delivering Fabrication Drawings that are:

- Technically Sound

- Code-Compliant

- Visually Clear

- Budget-Friendly

- Deadline-Oriented

- Our Social Presence – LinkedIn

Whether you’re building a complex industrial plant or a sleek architectural facade, our drawings will guide your fabrication process with confidence and clarity.

GET IN TOUCH FOR