3D Chemical Reactor Engineering: Precision Mixing & Processing Module

Our 3D Chemical Reactor Engineering has given chemical Reactor fabrication project delivers a turnkey, state-of-the-art solution for pharmaceutical and chemical plant applications—realized through expert engineering consultancy. Based on a comprehensive 3D model, this skid-mounted reactor integrates high-performance mixing, robust support structures, and precision-specified materials into a seamless assembly ready for rapid deployment.

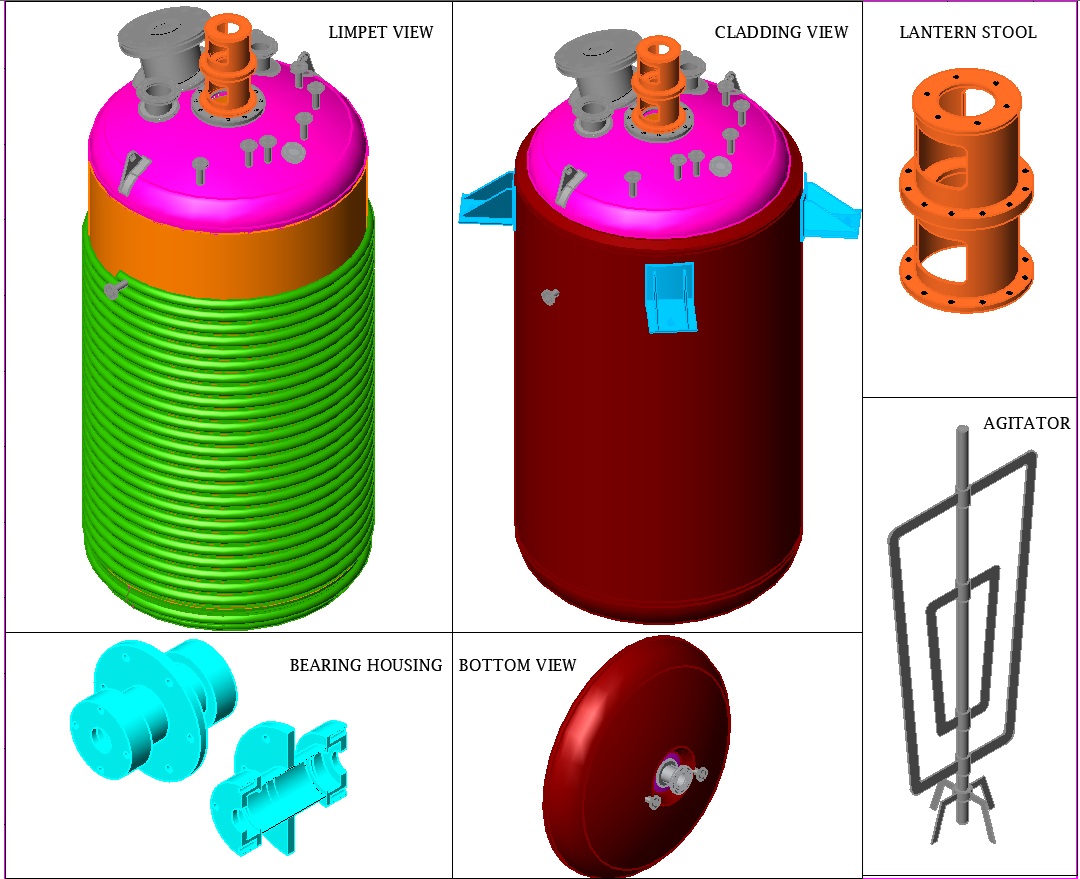

Key Components & Features

- Lantern Stool Support

• Heavy-duty steel construction (IS2062) with vibration-dampening mounts

• Maintenance-friendly access for shaft seal inspection and lubrication - Motor Assembly

• Industrial-grade, energy-efficient motor sized for design torque and speed

• Shaft alignment tolerances and service clearances detailed for flawless installation - Reactor Vessel & Materials

• Pressure-rated shell fabricated in IS2062 carbon steel for structural integrity

• Internal wetted surfaces lined or constructed in SS316L for superior corrosion resistance - Instrumentation & Nozzles

• CIP spray ball, thermowell, level and pressure gauge ports pre-flanged

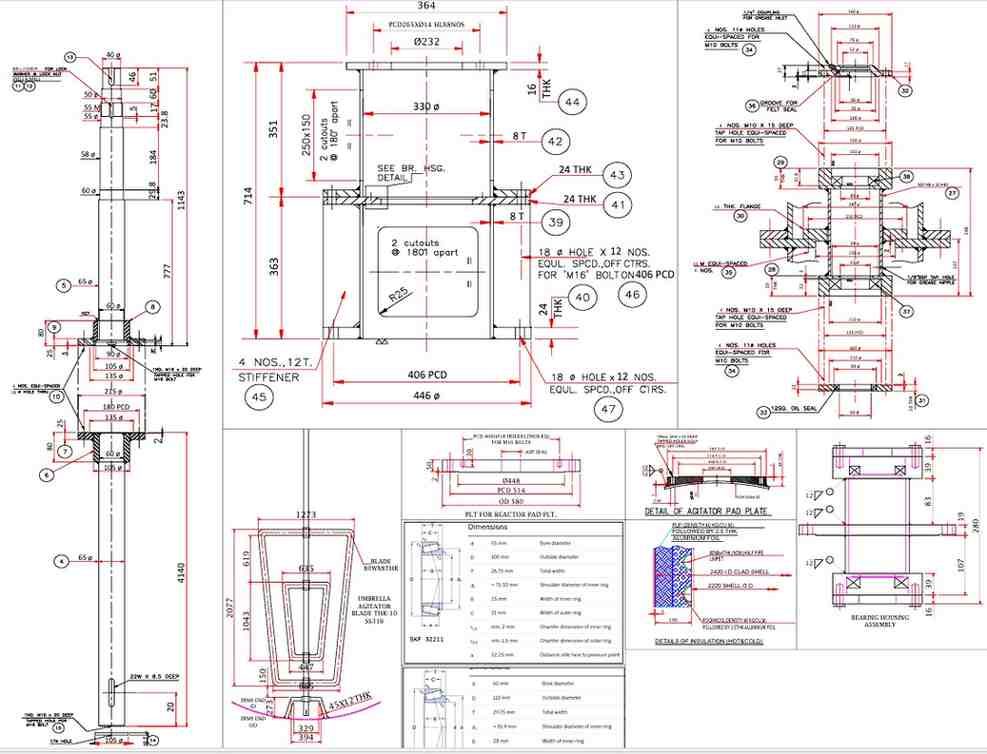

• Drain, vent, and sampling nozzles positioned for ergonomic access - Shaft design and lantern mountings are shown below:

Design & Consultancy Excellence

Leveraging advanced 3D Chemical Reactor Engineering, our team delivered:

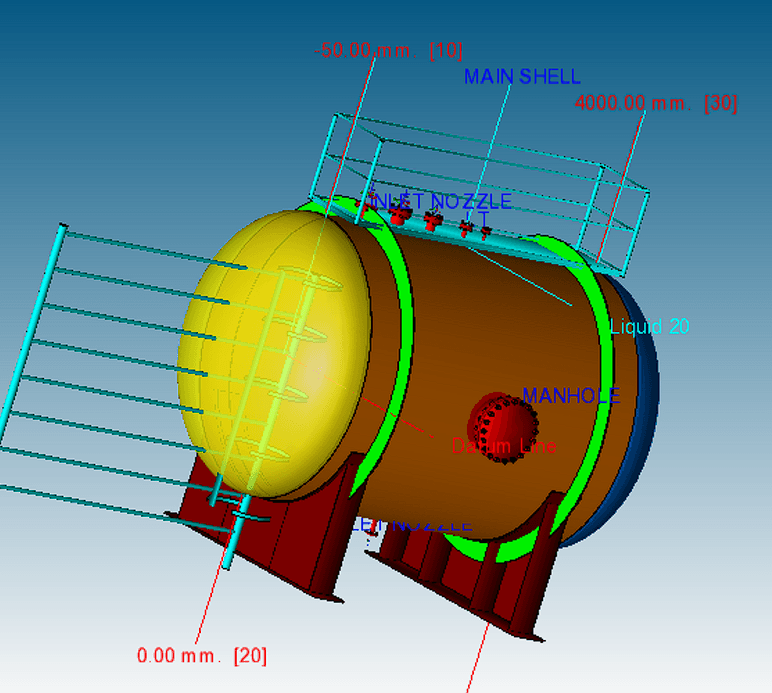

- Fully detailed 3D Chemical Reactor Engineering assembly and exploded-view models

- Comprehensive 2D fabrication drawings with dimensional tolerances and weld symbols

- Bill of materials listing every IS2062 and SS316L component, fastener, gasket, and coating

- Piping & instrumentation diagram (P&ID) references ensuring process alignment

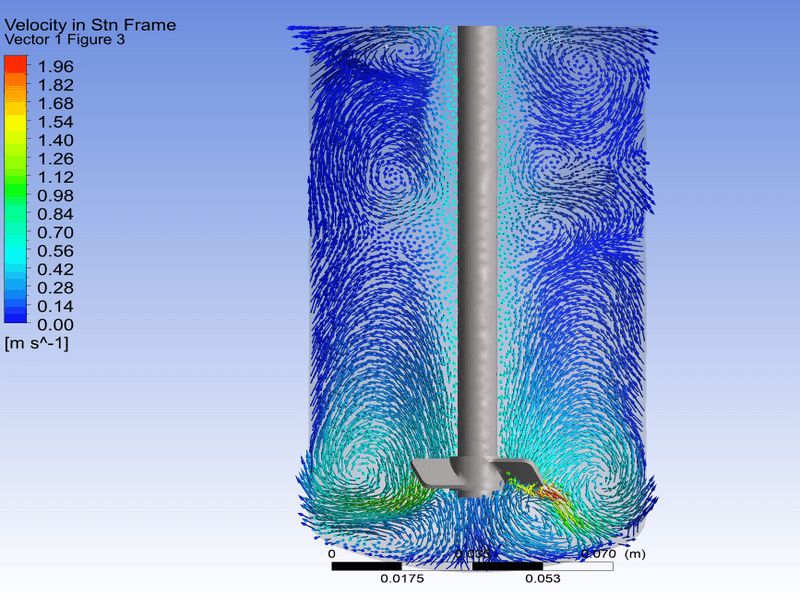

- Finite element analysis validating vessel stress limits and support load capacities

- Clash-detection workflows eliminating interferences before procurement

Every element is specified to reduce field modifications by up to 30%, accelerate fabrication, and ensure regulatory compliance.

Benefits & Deliverables

- Rapid, plug-and-play integration with existing skid layouts

- Unrivaled operational reliability backed by industrial-grade materials and precision CAD outputs

- Full documentation package: native CAD files, BOM reports, material traceability certificates, and FAT protocols

- Streamlined revision control and collaborative review enabled by cloud-based CAD platforms.

Precision Meets Performance

In 3D Chemical Reactor Engineering, reactors are the heart of process industries—from pharmaceuticals and petrochemicals to food processing and specialty chemicals. Designing reactors requires not only a command over CAD platforms but also an understanding of thermodynamics, fluid dynamics, material compatibility, and safety codes. Our consultancy stands out for translating intricate chemical reaction parameters into executable 2D and 3D CAD drawings that streamline fabrication, assembly, and future maintenance.

Every drafted reactor design goes through rigorous validation against ASME and RINA standards, ensuring client confidence and regulatory compliance. Our deliverables include detailed fabrication drawings, P&IDs, nozzle orientation layouts, support calculations, and integrated piping connectivity—all tailored to maximize efficiency and reduce downtime.

Client-Centric, Concept-to-Commissioning Support

What sets our CAD drafting approach apart is the synthesis of academic rigor and hands-on field experience. Having led multiple site execution projects, we understand the nuances often overlooked in purely theoretical designs. This enables us to foresee fabrication challenges, propose budget-conscious optimizations, and enhance long-term plant scalability.

From conceptual sketches to full-scale reactor modeling, we work closely with clients, vendors, and commissioning teams to ensure smooth project transitions. Our reactors are not just digitally perfect—they’re practically buildable and operable.

Innovation in Action

We don’t just draft; we solve. Our consultancy thrives on integrating multidisciplinary feedback loops—from chemical engineers and fabricators to operations managers and educators. This allows us to introduce smart design practices such as modular reactor assemblies, space-efficient layouts, and digital twin modeling.

With a firm belief in bridging industry and academia, we also channel our reactor design workflows into student challenges, enabling young engineers to explore real-world design variables using simulation tools and drafting software.

Proven Value for Global Projects

Whether it’s a jacketed reactor for temperature-sensitive reactions or a high-pressure autoclave for catalytic processes, our consultancy’s portfolio reflects a diverse range of successfully executed projects across sectors. Clients benefit not only from our drafting precision but also from our ability to visualize operational bottlenecks and propose proactive design tweaks.

Our drafting capabilities extend beyond reactors—covering vessels, heat exchangers, structural frameworks, and integrated plant layouts. Every drawing serve as a blueprint for performance, reliability, and innovation.

By marrying cutting-edge design with our CAD drafting engineering consultancy expertise, this chemical reactor module exemplifies precision, safety, and scalable performance tailored to the most demanding chemical and pharmaceutical processes.

GET IN TOUCH FOR A