CAD Drafting & 3D Modeling for Shed Design

At Core Design Center, we specialize in factory shed design and warehouse shed planning that combines structural integrity with cost-effective execution. Whether you’re setting up a new industrial unit, expanding your manufacturing facility, or optimizing storage space, our shed designs are tailored to meet your operational, environmental, and budgetary needs.

What Is Factory Shed Design?

Factory shed design refers to the architectural and structural planning of industrial sheds used for manufacturing, assembly, storage, or logistics. These sheds are engineered to withstand heavy loads, harsh weather conditions, and dynamic workflows—making them essential for MSMEs, large-scale industries, and logistics hubs.

Our designs are not just functional—they’re scalable, modular, and compliant with local building codes and safety standards.

Our Expertise in Industrial Shed Design

We offer end-to-end solutions for:

- Pre-engineered building (PEB) sheds

- Steel structure sheds

- MS fabrication sheds

- Warehouse layout planning

- Ventilation and lighting optimization

- Foundation and column detailing

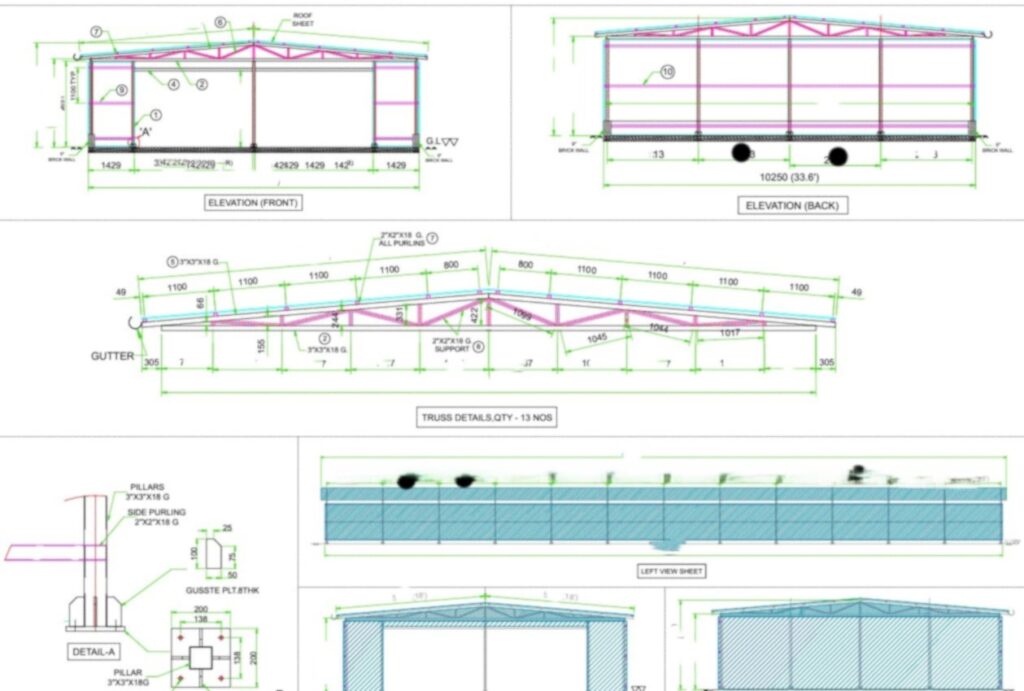

- Roof truss and purlin design

- Rainwater harvesting and drainage integration

Each factory shed design is customized based on your site conditions, machinery layout, workflow requirements, and future expansion plans.

CAD Drafting & 3D Modeling for Shed Design

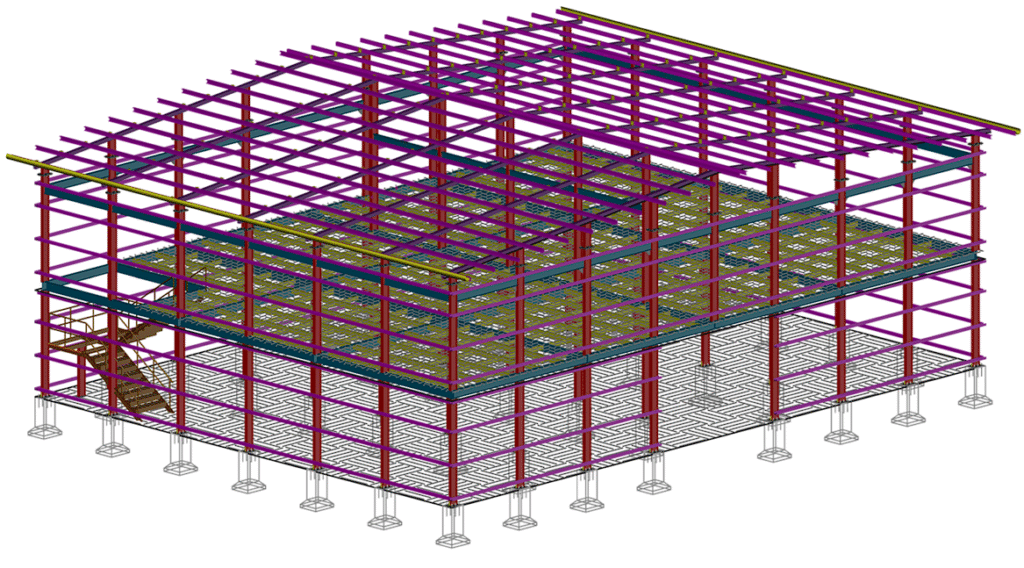

Our team uses advanced CAD drafting and 3D modeling tools to visualize your shed before construction begins. This allows for:

- Accurate load calculations

- Clash detection and layout optimization

- Material estimation and cost control

- Easy approvals from local authorities

We provide detailed 2D drawings, structural plans, and 3D visualizations that help you make informed decisions and reduce on-site errors.

Design Calculations in PEB Shed Design: Engineering Strength with Precision

Pre-Engineered Building (PEB) shed design is a structural solution that combines speed, scalability, and cost-efficiency. At Core Design Center, we approach every PEB shed design with rigorous engineering calculations to ensure safety, durability, and compliance with IS and ASME standards. These calculations form the backbone of your industrial shed—whether it’s for manufacturing, warehousing, or logistics.

Key Parameters in PEB Shed Design Calculations

- Load Analysis

We begin by calculating dead loads (self-weight of structural components), live loads (occupancy and usage), wind loads (based on local wind zones), and seismic loads (as per IS 1893). These are critical for determining column sizing, bracing requirements, and foundation depth. - Span and Bay Optimization

The spacing between columns (bays) and the total span of the shed directly affect material usage and cost. We use structural software to optimize these dimensions for maximum efficiency without compromising strength. - Roof Truss and Purlin Design

Trusses are designed to carry roof loads and transfer them to columns. Purlins are sized based on spacing, roof slope, and sheet weight. We calculate bending moments, shear forces, and deflection limits to ensure structural integrity. - Column and Beam Sizing

Using moment-resisting frame analysis, we determine the ideal cross-section for columns and beams. This includes checking for buckling, axial stress, and lateral-torsional stability. - Foundation Design

Based on soil bearing capacity and column loads, we design isolated or combined footings. Reinforcement detailing is done to resist uplift and lateral forces. - Connection Detailing

Bolted and welded connections are designed using shear and bearing strength calculations. We ensure that joints can safely transfer loads without fatigue or failure.

Software and Standards

We use tools for modeling and validation. All designs comply with IS 800, IS 875, and ASME Section VIII where applicable.

Factory shed design is not just about steel—it’s about science. At Core Design Center, we turn numbers into structures that stand the test of time. Whether you’re building a fabrication unit or a logistics hub, our calculation-driven approach ensures your shed is safe, scalable, and future-ready.

Why Choose Core Design Center for Factory Shed Design?

Custom Design Solutions -Tailored to your industry, workflow, and budget

Engineering Precision– Designs validated with structural software and compliance checks

Fast Turnaround – Optimized workflows for quick delivery of drawings and models

Site Execution Support – On-ground expertise for fabrication and installation

Scalable & Modular Designs – Future-proof layouts that grow with your business

SEO-Optimized Documentation – Drawings and content ready for digital presentation and client outreach

Our Social Presence – LinkedIn

Applications of Our Shed Designs

- Manufacturing Units – CNC, fabrication, assembly lines

- Storage Warehouses – FMCG, pharma, agricultural goods

- Logistics Hubs – Loading bays, dispatch centers

- Cold Storage Facilities – Temperature-controlled environments

- Workshops & Service Bays – Automotive, electrical, repair stations

Ready to Build Your Industrial Future?

Whether you need a compact fabrication shed or a large-scale warehouse facility, Core Design Center delivers shed designs that are strong, smart, and scalable. Our factory shed design services empower MSMEs and industrial clients to build with confidence, clarity, and compliance.

GET IN TOUCH FOR