In the world of Part Drawings engineering design, precision isn’t a luxury—it’s a necessity. Whether you’re prototyping a new product or reverse-engineering legacy machinery, assembly and part drawings form the backbone of any successful CAD drafting workflow. For engineering consultants, especially those serving MSMEs and industrial clients, mastering these drawings is not just about technical accuracy—it’s about delivering clarity, compliance, and cost-effective execution.

1. What Are Assembly and Part Drawings?

At their core, part drawings are detailed representations of individual components, while assembly drawings show how these parts fit together to form a complete product or system. These drawings are essential for:

- Manufacturing and fabrication

- Quality control and inspection

- Maintenance and repair

- Procurement and inventory management

For engineering consultants, these documents serve as a universal language between design teams, vendors, and production units—bridging the gap between concept and reality.

2. Why Part Drawings Are the Cornerstone of CAD Drafting

Using part drawings as a focus keyword isn’t just SEO-smart—it reflects their central role in industrial design. Here’s why they matter:

- Dimensional Accuracy: Every bolt hole, chamfer, and tolerance is captured.

- Material Specification: From stainless steel to ABS plastic, part drawings define what goes into production.

- Process Clarity: Machining, casting, or 3D printing—each process demands tailored drawings.

- Compliance: Adhering to ASME, ISO, or BIS standards ensures legal and operational safety.

Delivering high-quality part drawings means fewer revisions, faster approvals, and happier clients.

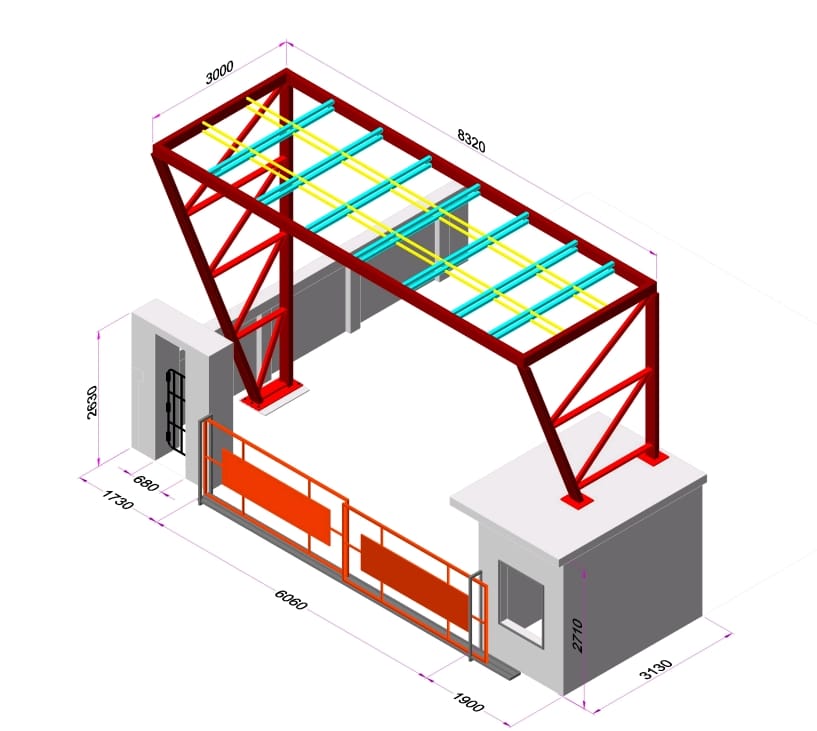

3. Smart Layering: The Secret to Scalable Assembly Drawings

One of the most overlooked techniques in CAD drafting is layer management. By organizing components into logical layers—mechanical, electrical, pneumatic—you create drawings that are:

- Easier to interpret

- Faster to edit

- More adaptable for future upgrades

Layering also helps consultants offer modular documentation, which is especially useful for MSMEs scaling their operations or customizing products for different markets.

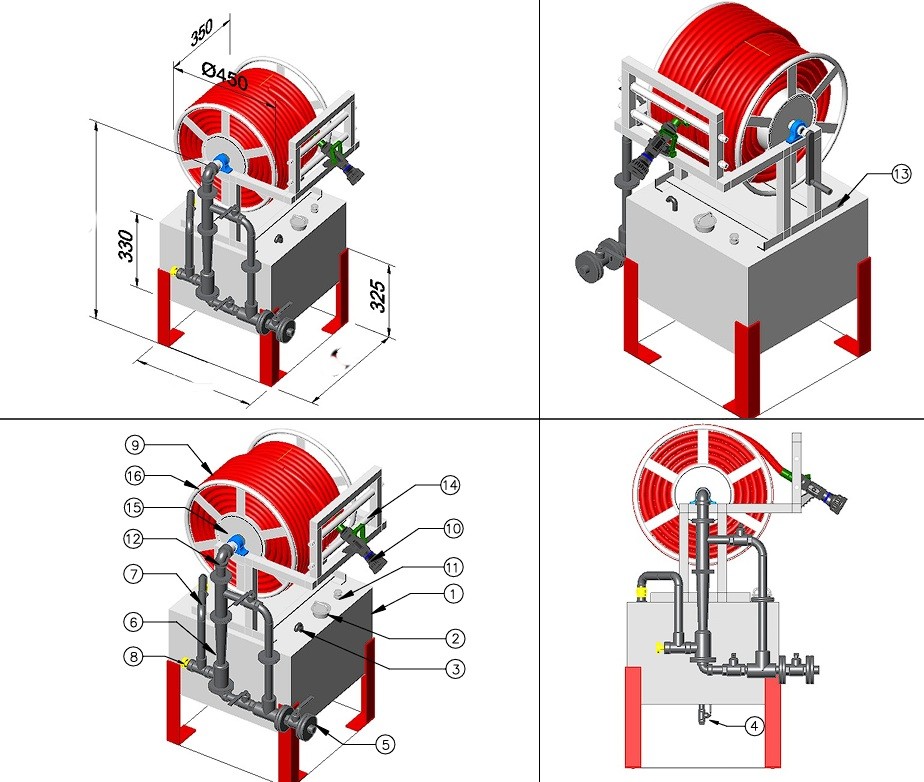

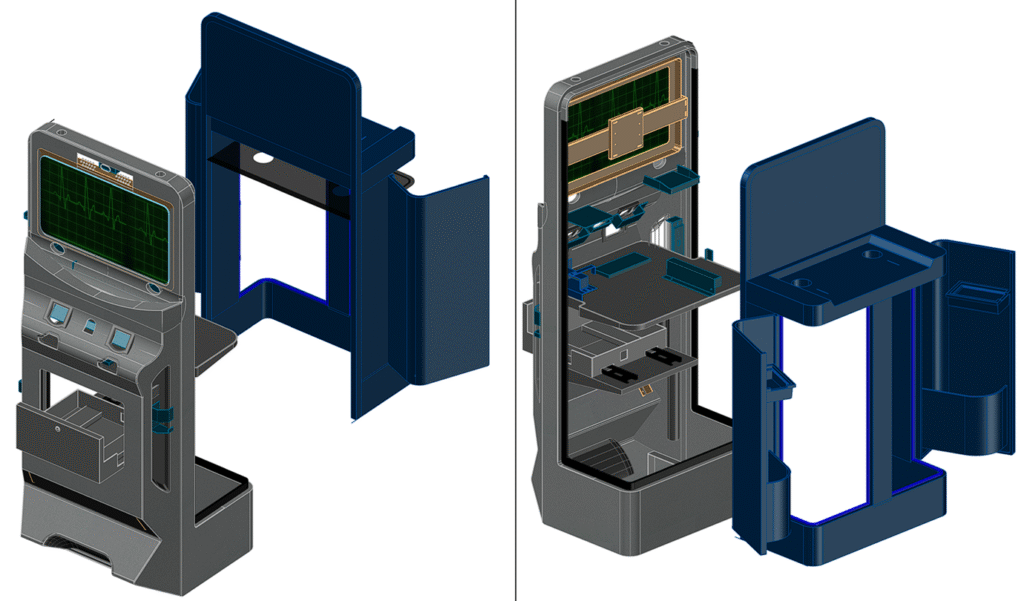

4. From 2D to 3D: Elevating Part Drawings with Visual Intelligence

While traditional 2D drawings remain essential for fabrication, integrating 3D modeling into your workflow offers powerful advantages:

- Exploded Views: Help clients visualize complex assemblies

- Sectional Analysis: Reveal internal features without clutter

- Simulation Ready: Enable stress tests and motion studies

5. BOM Integration: Turning Drawings into Actionable Data

A well-crafted assembly drawing isn’t complete without a Bill of Materials (BOM). Integrating BOMs directly into your CAD files allows:

- Seamless procurement

- Accurate cost estimation

- Streamlined inventory control

6. Custom Templates: Branding Meets Engineering

For consultants working with small and medium enterprises, offering custom drawing templates can be a game-changer. These templates include:

- Company logo and branding

- Pre-set title blocks and revision history

- Standardized dimension styles and annotations

- Our Social Presence: LinkedIn

Not only do these templates enhance professionalism, but they also reduce onboarding time for new clients and ensure consistency across projects.

7. Quality Control & Revision Tracking: The Consultant’s Edge

In industries where compliance and traceability are critical, revision tracking and quality control annotations in part drawings are non-negotiable. Best practices include:

- Version-controlled file naming

- Cloud-based drawing repositories

- QR codes linking to digital specs or videos

Why Choose CORE DESIGN CENTER for Precision Part Drawings?

1. Technically Robust, Field-Tested Expertise

Our team blends CAD mastery with on-site execution experience, ensuring that every part drawing is not only technically sound but also practically buildable. Whether you’re designing pressure vessels, structural components, or custom equipment, we validate every spec against real-world constraints.

2. End-to-End CAD Drafting Solutions

From 2D detailing to 3D modeling, we offer a full spectrum of services under one roof:

- Fabrication-ready part drawings

- Assembly drawings with BOM integration

- Civil, architectural, and facade detailing

- Design analysis for tanks and structures

3. Uncompromised Detailing & Documentation

We don’t just meet standards—we exceed them. Our part drawings comply with:

- ASME Section VIII

- API, ISO, PD, IS 875, IS 1893

- B16.5, B16.9, B16.11 and more

4. On-Time, Cost-Effective Delivery

We understand that delays cost money. That’s why our workflows are optimized for speed without sacrificing quality. Whether you’re an MSME or an EPC contractor, we deliver part drawings that are:

- Budget-aligned

- Deadline-driven

- Ready for fabrication or client submission

Final Thoughts: CAD Drafting as a Strategic Asset

Assembly and part drawings aren’t just technical deliverables—they’re strategic assets. For engineering consultants, and industrial clients, these drawings can:

- Accelerate product development

- Reduce manufacturing errors

- Strengthen client relationships

- Open doors to new markets

GET IN TOUCH FOR A