CO₂ Process Skid Design: Precision-Engineered CO₂ Handling & Treatment Module

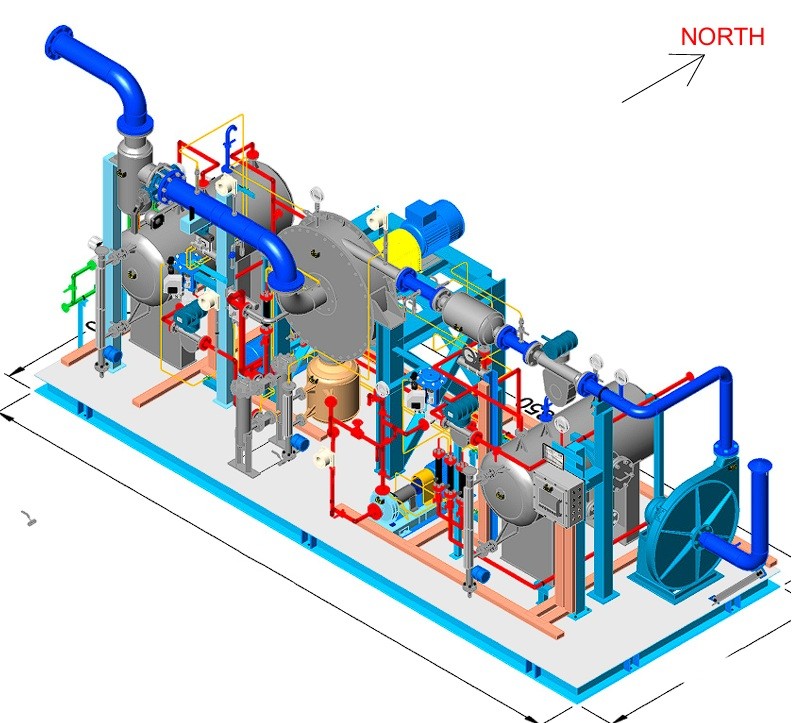

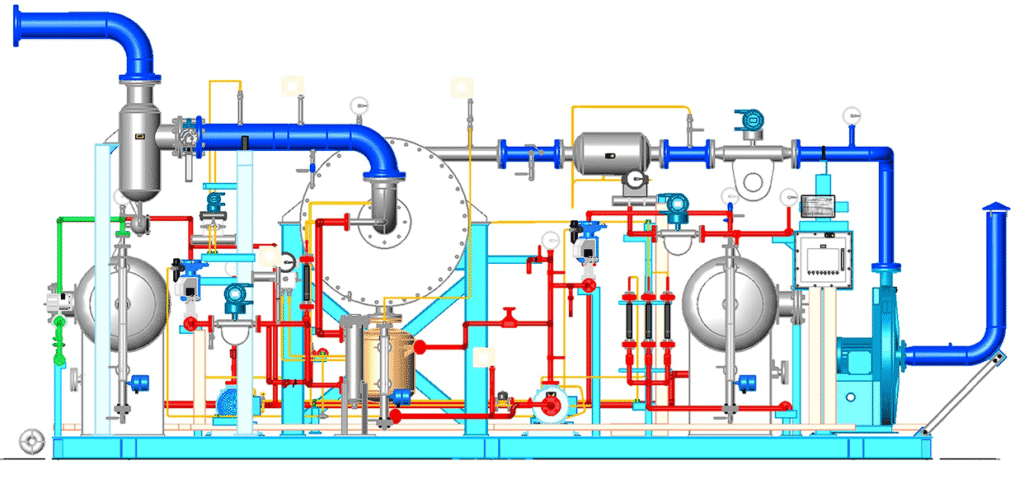

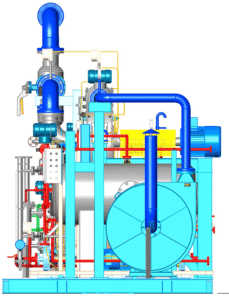

Our CO₂ Process Skid Design project delivers a turnkey, state-of-the-art solution for gas handling, mixing, pumping, and storage—fully realized through expert CAD drafting engineering consultancy. Based on a detailed 3D model, this modular skid integrates high-efficiency components into a compact, transportable frame, ensuring rapid on-site deployment and seamless integration with existing process lines.

What Is a CO₂ Process Skid?

A Process Skid Design is a self-contained unit that houses all necessary equipment—pumps, compressors, heat exchangers, control panels—mounted on a frame for easy transport and installation. In the context of CO₂ recovery, these skids are engineered to:

- Capture CO₂ from flue gas or industrial emissions

- Compress and store CO₂ in liquid or supercritical form

- Interface with pipeline, truck, or rail systems for distribution or sequestration

This modular approach allows for plug-and-play deployment, reducing downtime and installation costs while ensuring high performance and safety standards.

Design Highlights of the CO₂ Skid System

The CO₂ Process Skid Design incorporates advanced technologies such as:

- Amine-based scrubbing systems for chemical absorption

- Cryogenic separation units for high-purity CO₂ extraction

- Membrane absorption modules for compact and efficient capture

- Liquid ring compressors to handle saturated flue gases without corrosion risks

Each skid undergoes Factory Acceptance Testing (FAT) to ensure operational integrity before delivery, making it a reliable alternative to traditional on-site builds.

Applications Across Industries

CO₂ skid systems are being deployed in:

- Power plants for post-combustion carbon capture

- Refineries and chemical plants for process emissions control

- Food and beverage industries for CO₂ reuse in carbonation

- Enhanced oil recovery (EOR) operations via pipeline injection

Their compact footprint and modular scalability make them ideal for both large-scale facilities and smaller operations seeking compliance with emission norms.

Benefits of Modular Process Skid Design

- Speed: Off-site fabrication accelerates project timelines

- Safety: Controlled environments reduce fabrication risks

- Flexibility: Easily customized for site-specific requirements

- Integration: Seamless connection to existing infrastructure

These advantages position Process Skid Design as a cornerstone of modern carbon management strategies.

Engineering for Tomorrow

The CO₂ Process Skid Design Project is more than just a technical achievement—it’s a strategic response to environmental challenges. By combining engineering precision with modular innovation, these systems enable industries to meet sustainability goals without compromising operational efficiency.

As demand for carbon capture grows, process skid engineering will continue to evolve, incorporating smart automation, remote monitoring, and AI-driven optimization. The future of CO₂ recovery is compact, intelligent, and ready to roll.

Modern process skid design is increasingly integrating smart automation and remote diagnostics, allowing operators to monitor CO₂ flow rates, pressure levels, and system health in real time. This not only enhances operational safety but also supports predictive maintenance and energy optimization. With growing interest in carbon credits and ESG compliance, CO₂ skid systems offer a tangible path toward measurable sustainability. Whether deployed in a pilot plant or full-scale facility, these modular units are redefining how industries approach carbon capture and utilization (CCU). The CO₂ Process Skid Design Project is not just engineering—it’s environmental stewardship in action.

Key Components & Features

- Static Mixer

• CFD-optimized mixing elements guarantee homogenous gas–liquid blending

• Sanitary design minimizes pressure drop and maintenance downtime - Pumps

• Redundant, corrosion-resistant centrifugal pumps sized for design head and flow rates

• API-compliant seals and bearings ensure long MTBF in demanding applications - ASME-Certified Tanks

• Vertical pressure vessels rated to 150 psig, complete with relief devices and level instrumentation

• Fabricated per Section VIII, Division 1 for maximum safety and regulatory compliance.

Design & Consultancy Excellence

Leveraging advanced CAD drafting engineering consultancy, our team produced a fully detailed 3D assembly drawing, 2D fabrication prints, and P&ID schematics. Every weld, flange, and instrument tag were specified for precision fit-up, reducing field modifications by up to 30%. Finite element analysis verified structural integrity under dynamic loads, while clash-detection workflows eliminated piping interferences before procurement.

Benefits & Deliverables

- Accelerated project timelines with plug-and-play skid layout

- Enhanced operational reliability through ASME/CE-certified components

- Full documentation package: 3D CAD files, material traceability reports, and FAT procedures

By creating robust design with expert CAD drafting engineering consultancy, this CO₂ skid exemplifies precision, safety, and scalable performance tailored to your process requirements.

GET IN TOUCH FOR