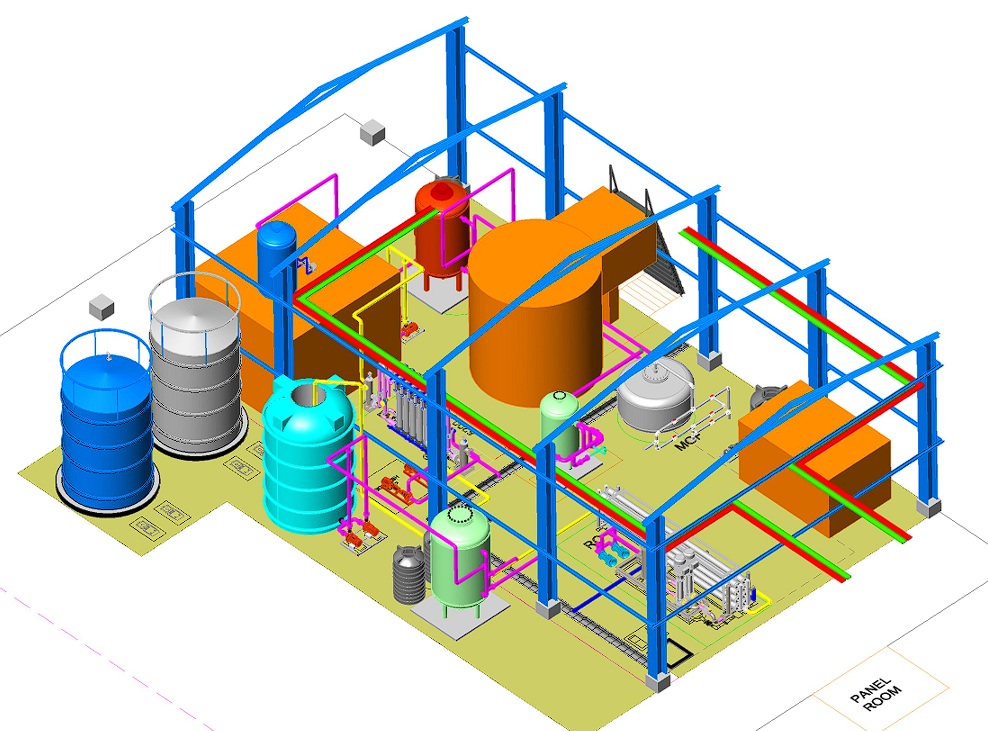

Elite advanced 3D Modelling & Engineering Precision for Advanced RO Plant Design

In today’s Advanced Process Plant 3D Modelling, the demand for efficient and high-performance water purification systems has never been greater. Reverse Osmosis (RO) plants are at the forefront of this movement, providing scalable and reliable solutions for a wide range of sectors—from pharmaceuticals and petrochemicals to food processing and energy production.

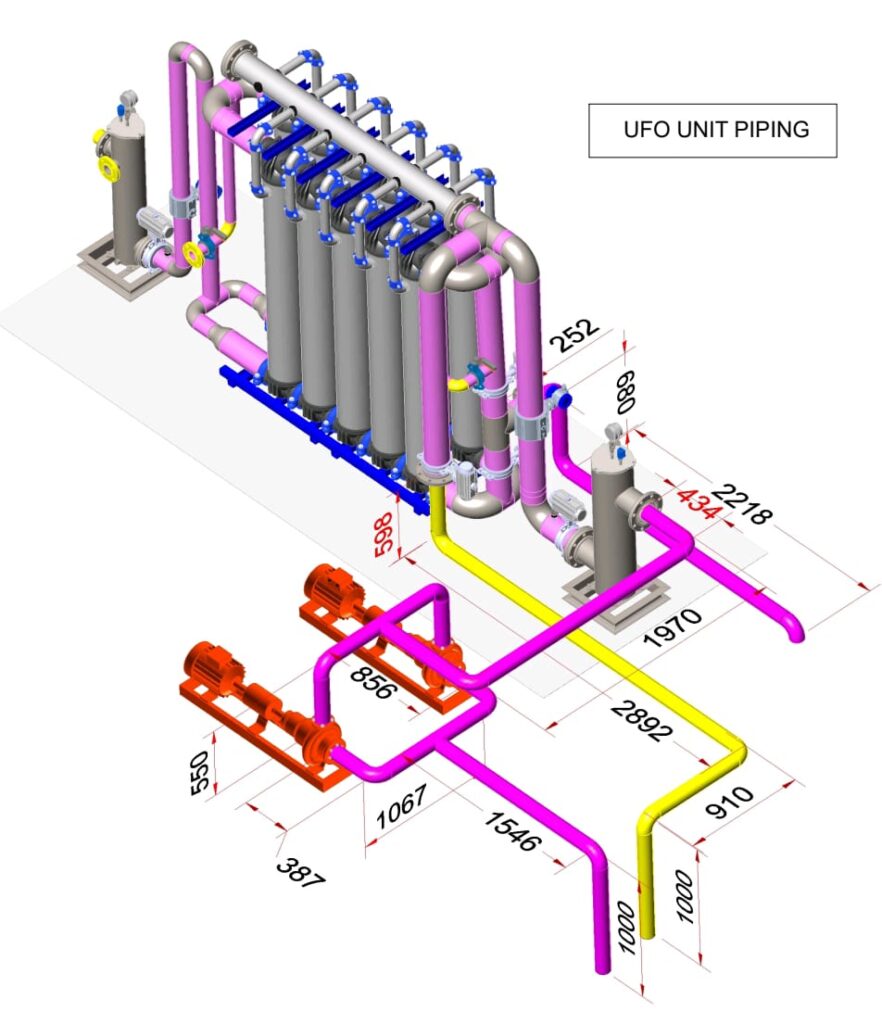

One of the pivotal advancements transforming RO plant execution is the integration of cutting-edge 3D design, enhanced by meticulous process and mechanical calculations and precision-driven fabrication detailing. This complete ecosystem of design and detailing is now being supercharged by CAD drafting engineering consultancy, offering businesses a competitive edge in system optimization and project delivery.

The Power of 3D Design in RO Plants-

The transition from traditional drafting methods to advanced 3D modelling empowers engineering teams to visualize and refine RO plant configurations with remarkable accuracy. Every pipe, pump, and pressure vessel are digitally mapped, eliminating spatial conflicts and enabling real-time adjustments. The benefits include:

- Enhanced visual representation for stakeholder clarity

- Real-time simulation of fluid dynamics and flow rates

- Seamless integration with existing infrastructure layouts

Through smart 3D CAD platforms, engineers can not only visualize the plant but also pre-emptively address potential design flaws—saving weeks of post-installation adjustments and reducing overhead costs.

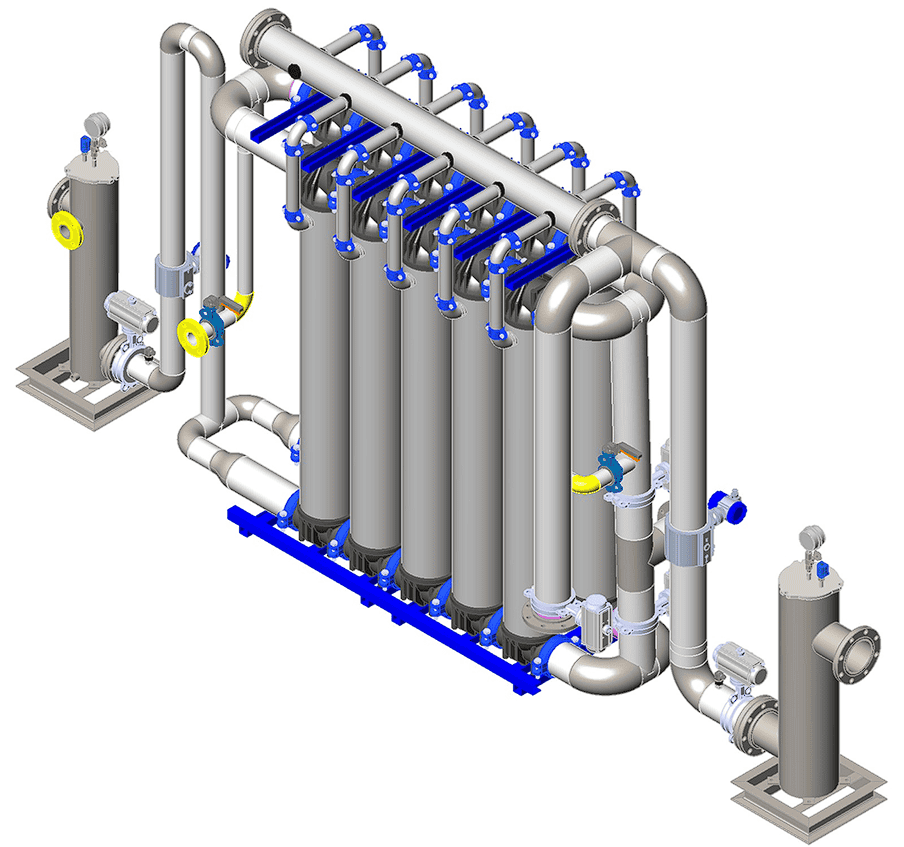

Precision Process and Mechanical Calculations –

Behind every successful RO plant is a backbone of accurate engineering calculations. Process engineers focus on variables such as TDS (Total Dissolved Solids) load, recovery rate, permeate flow, and energy consumption. Mechanical engineers, on the other hand, address:

- Pressure ratings and structural integrity of components

- Thermodynamic behavior during operation cycles

- Material compatibility with chemical reagents and temperature shifts

These calculations are crucial for operational longevity, regulatory compliance, and maximizing water recovery efficiency. When performed in synergy with Advanced Process Plant 3D Modelling consultancy, these calculations directly inform the plant’s spatial configuration and fabrication documentation.

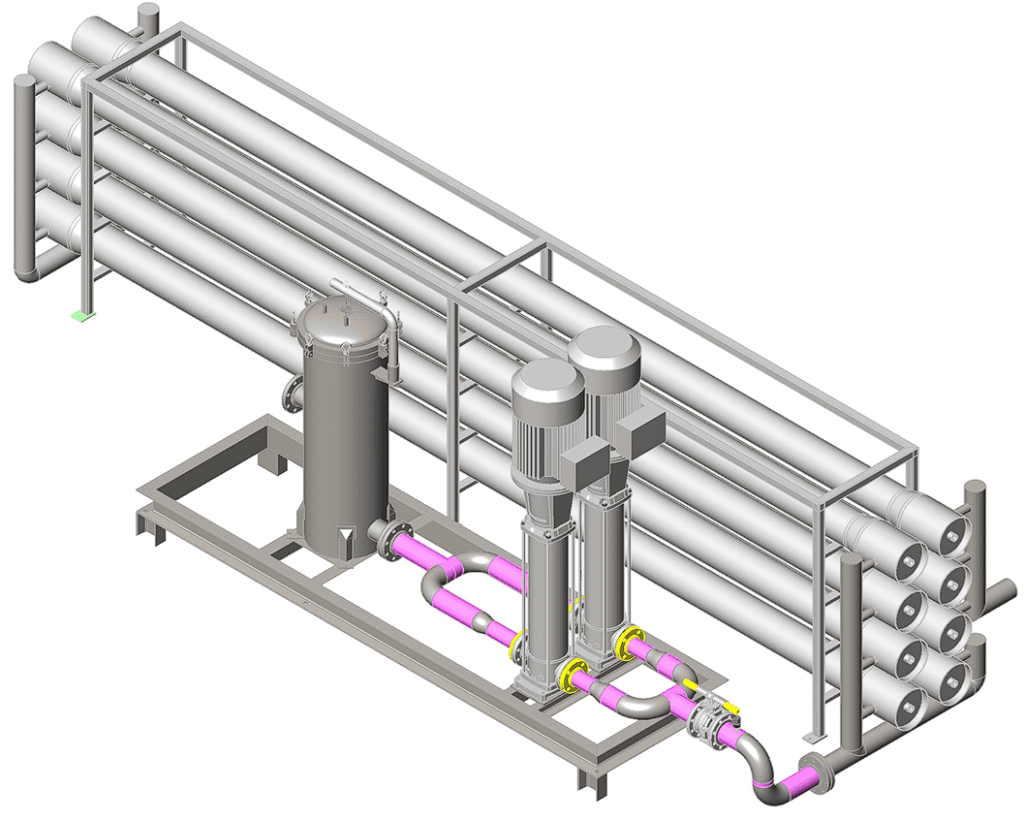

Fabrication Detailing: Where Design Meets Reality-

Fabrication detailing bridges the gap between ideation and construction. It involves producing shop drawings that specify:

Weld types, flange details, and bolting specifications.

Plate thickness, bracket placements, and support frame designs

Isometric views and exploded assemblies for manufacturing clarity.

A specialized CAD drafting engineering consultancy transforms these details into production-ready documents, ensuring that manufacturing teams can proceed confidently with precise instructions. Errors are minimized, timelines are accelerated, and compliance with engineering codes.

Why CAD Drafting Engineering Consultancy Is Essential –

Partnering with a CAD drafting engineering consultancy is no longer optional—it’s a strategic necessity. These consultancies leverage state-of-the-art drafting tools and industry expertise to deliver:

Intelligent design iterations based on client feedback

Accelerated design-to-delivery pipelines

Regulatory-grade documentation for industry audits

Our Social Presence – LinkedIn

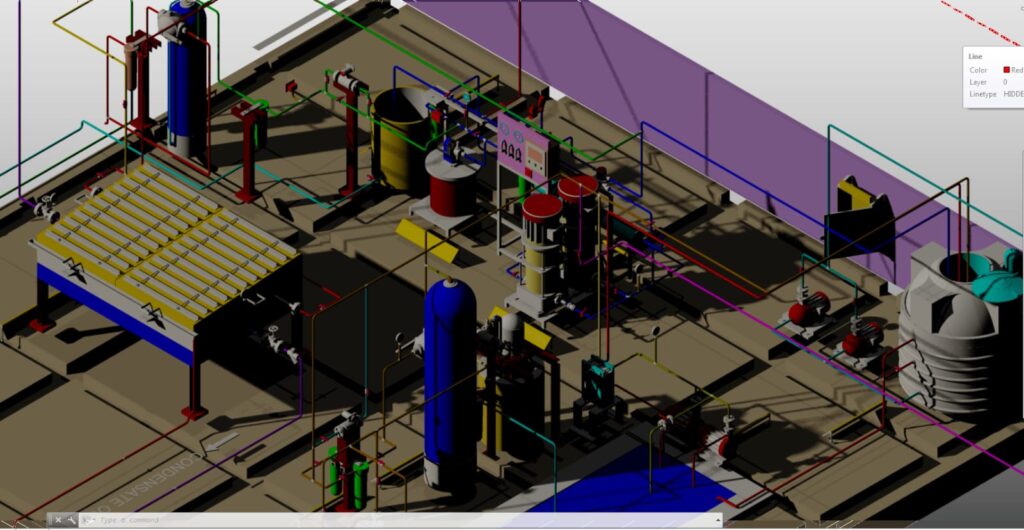

Their role goes beyond simple drafting—they actively enhance design accuracy, ensure data integrity across design platforms, and streamline cross-disciplinary collaboration. A precision-driven consultancy doesn’t just deliver designs—it drives engineering innovation. From lightweighting structures using topology optimization to designing for manufacturability (DFM) and sustainability, these experts bridge the gap between vision and execution.

With the rise of Industry 4.0, integrating intelligent systems, IoT devices, and smart manufacturing into the product lifecycle is crucial. A cutting-edge consultancy leverages digital twins, data-driven modelling, and agile engineering processes to help clients stay ahead of market trends.

Final Thoughts

As RO plants become more complex and central to industrial operations, the synergy of 3D design, process/mechanical calculations, and precise fabrication detailing is revolutionizing how these systems are conceived and built. The CAD drafting engineering consultancy model stands at the crossroads of innovation, productivity, and quality control—delivering smarter, safer, and more sustainable water treatment systems for industries worldwide.

Ready to optimize your RO plant project? Make the smart move by teaming up with a consultancy that understands the blueprint for engineering success.

GET IN TOUCH FOR