Precision in Storage: API Standard Tank Design with Engineering Consultancy Excellence

In the API Standard Tank Design, industrial infrastructure, storage tanks designed to API 650 and API 620 standards stand as pillars of safety, precision, and longevity. These globally recognized codes ensure reliability across sectors like petrochemicals, water treatment, and chemical processing, particularly when engineered with a strategic emphasis on quality CAD drafting and smart fabrication.

At the forefront of this evolution is our API Standard Tank Design engineering consultancy, offering end-to-end tank design solutions that blend technical rigor with visualization mastery. From shell plate configurations to structural support systems, every element is conceptualized to meet performance, compliance, and cost-efficiency targets.

API Standard Tank Design Structural Highlights

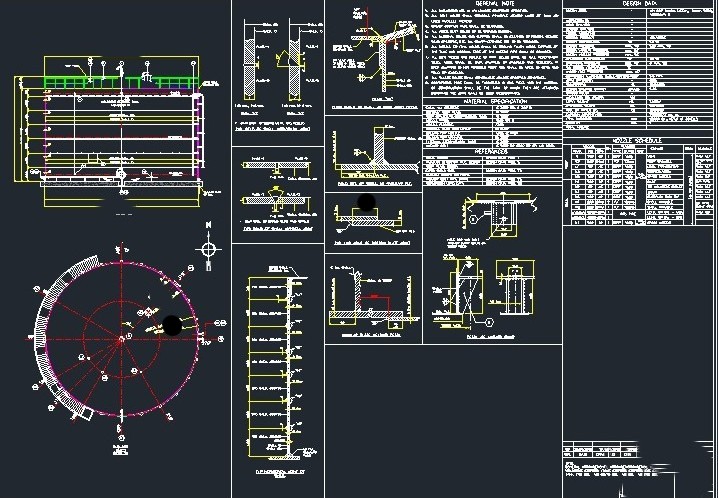

The tank’s vertical shell design adheres to API 650/620 mandates, accommodating low to moderate internal pressures. The shell is meticulously drafted using CAD tools to define:

- Plate thicknesses based on hydrostatic height

- Annular ring integration for enhanced bottom-to-shell transition

- Welded seams with calculated joint efficiency and inspection access

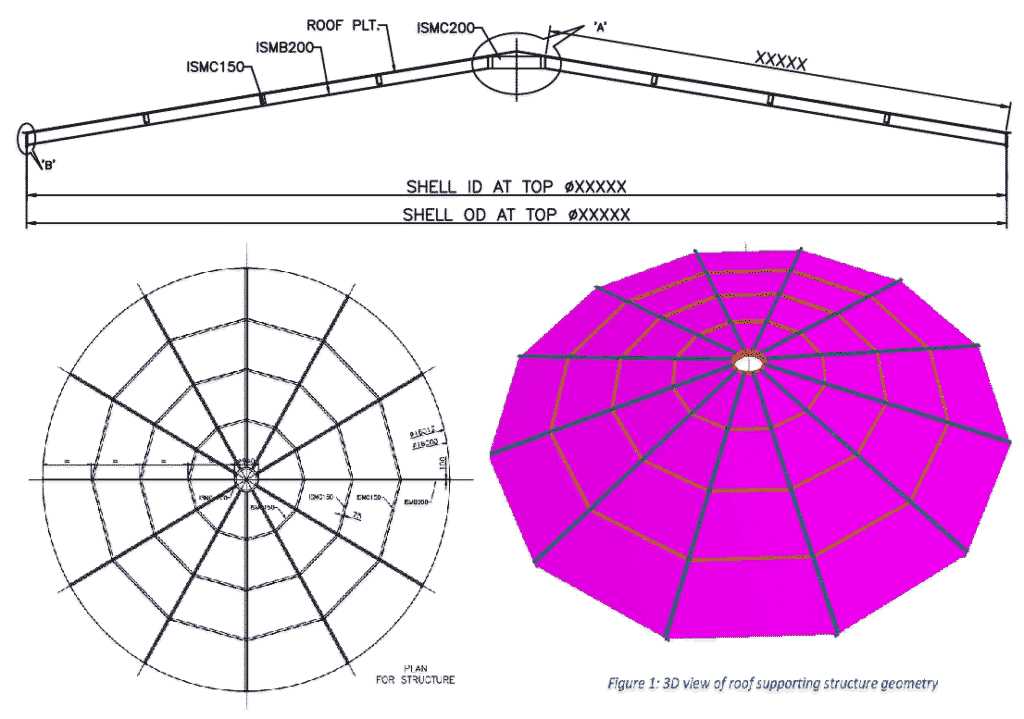

Complementing the shell, the roof plate design incorporates a self-supporting or supported structure, depending on load criteria and site conditions. For internal floating roofs or dome configurations, CAD detailing ensures plate nesting, stiffener placements, and accurate bolt hole arrays.

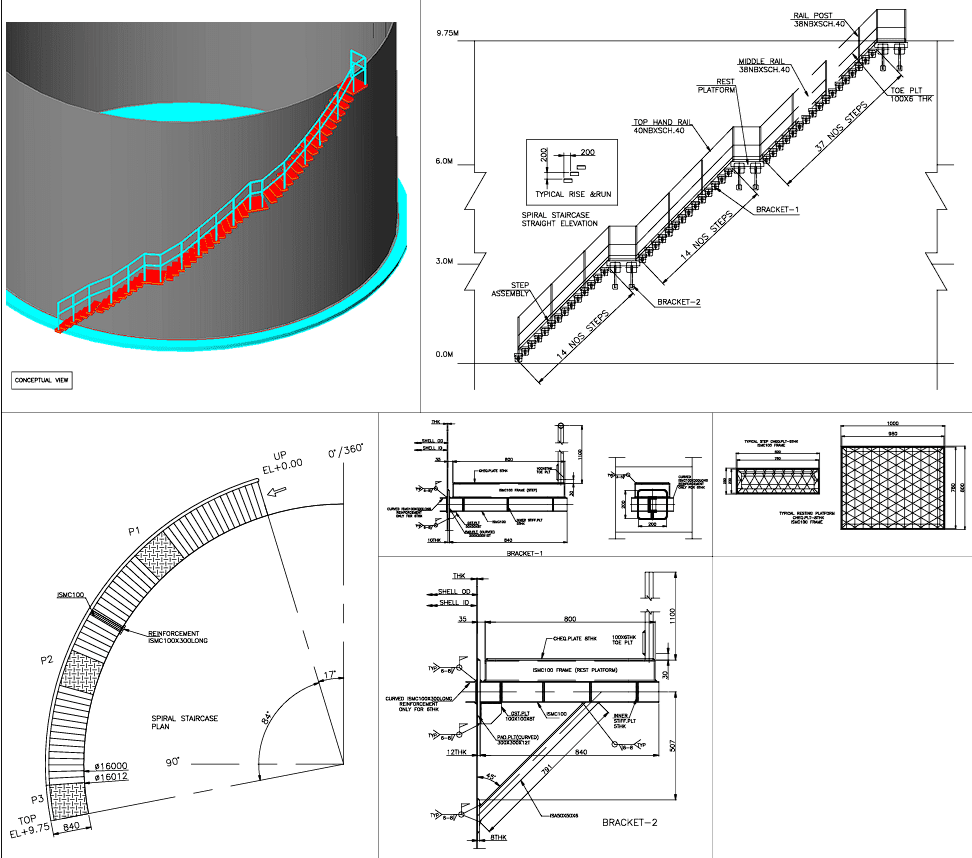

The inclusion of a spiral ladder with a peripheral top railing guarantees safe access and meets OSHA and IS code specifications. The slope, pitch, and tread spacing are derived through ergonomic modeling, while railing supports are anchored to structural members shown in exploded fabrication views.

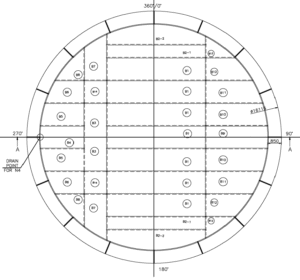

Plate Layout & Bottom Design

The shell plate layout drawing plays a central role in minimizing waste and ensuring easy erection. Through CAD nesting algorithms, plates are arranged to reduce off-cuts while maintaining structural symmetry.

At the base, the bottom plate layout is engineered with overlaps and slopes toward the drain point, ensuring effective liquid evacuation and protection from corrosion pockets. Overlap dimensions are guided by drainage velocity studies and API sump criteria. Visual representation through CAD layers shows welded lap joints, drain sump housing, and foundation anchoring pads.

Fabrication Drawing with MTO Integration

A hallmark of our API Standard Tank Design engineering consultancy is the ability to convert concept into fabrication-ready documentation with Material Take-Offs (MTOs). These detailed drawings include:

- Dimensional callouts, weld symbols, and tolerances

- Bill of materials listing each plate, bolt, nozzle, and bracket

- Cutting plans and heat number tagging for traceability

- Support structure and ladder fabrication sequences

This ensures that both fabrication units and on-site teams have a unified understanding of construction requirements, dramatically reducing project lag and miscommunication.

Engineering Value & Code Compliance

API 650 emphasizes tanks at atmospheric pressure, while API 620 expands the range to lower-pressure applications. Our consultancy bridges the gap between code clauses and real-world fabrication, ensuring:

- Seismic and wind load compliance

- Nozzle placement optimized for thermal expansion

- Stress analysis and finite element modeling (FEM) where needed

Each element of the API Standard Tank Design is scrutinized through digital simulations and documented via CAD for authority approvals and third-party verifications.

API (American Petroleum Institute) has a whole suite of standards beyond just 650 and 620, each tailored to specific equipment, materials, and operational conditions. Here are a few notable ones relevant to your domain:

- API 12B, 12D, 12F: Cover shop-fabricated tanks for upstream oil production

- Focus on standardized dimensions and quick deployment

- Focus on standardized dimensions and quick deployment

- 🔩 API 653 – Tank Inspection, Repair, Alteration, and Reconstruction

- Applies to tanks built under API 650

- Covers periodic inspection, corrosion evaluation, and repair procedures

- Essential for lifecycle management and compliance audits

- API 2000 – Venting Atmospheric and Low-Pressure Storage Tanks

- Specifies requirements for pressure/vacuum relief valves

- Critical for tanks storing volatile liquids or under thermal expansion

- API 2510 – Design and Construction of LPG Installations

- Focuses on liquefied petroleum gas storage and handling

- Includes tank spacing, fire protection, and safety systems

- API 5L / 1104 / 6A – Related to Piping and Welding

- API 5L: Line pipe specifications

- API 1104: Welding of pipelines and related facilities

- API 6A: Wellhead and Christmas tree equipment

- You might also encounter EN 14015 (European standard for above-ground welded tanks) and ASME Section VIII for pressure vessels, which sometimes overlap in scope depending on pressure and temperature ranges.

🛢️ API 650

Design & construction of welded steel tanks

- Pressure Range: Up to 2.5 psig

- Design Focus: Structural integrity, seismic/wind loads

- Temperature Range: -40°F to 500°F

🛢️ API 620

Design of large, low-pressure field-erected tanks

- Pressure Range: Up to 15 psig

- Design Focus-Pressure containment, cryogenic behavior

- Temperature Range: -325°F to 250°F

🛢️ API 653

Inspection, repair, and alteration of existing tanks

- Not applicable (focuses on service tanks)

- Design Focus: Corrosion, settlement, weld integrity

- Temperature Range: Depends on original tank design

Conclusion

A well-executed tank design is more than a sketch—it’s a blueprint of reliability. By harnessing precision tools and decades of multidisciplinary expertise, our CAD drafting engineering consultancy transforms API-standard design principles into fabricable solutions. Every bolt, plate, and weld reflect our commitment to excellence, safety, and industrial evolution.

Our Social Presence – LinkedIn

Let us help you visualize and execute the unseen—where compliance meets creativity, and fabrication flows from insight.

GET IN TOUCH FOR