Advanced Engineering Solutions for Circular Platform & ladder Design

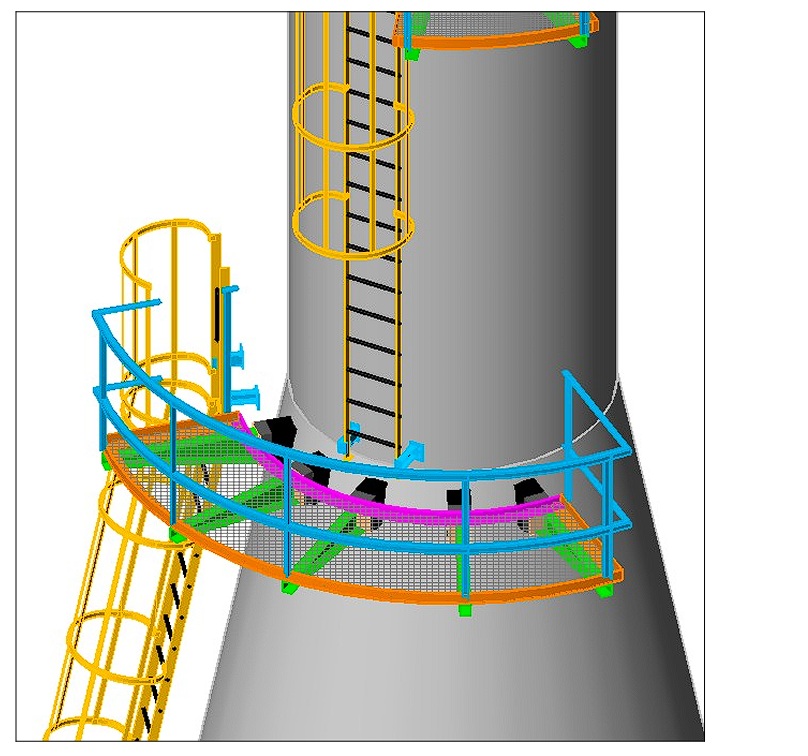

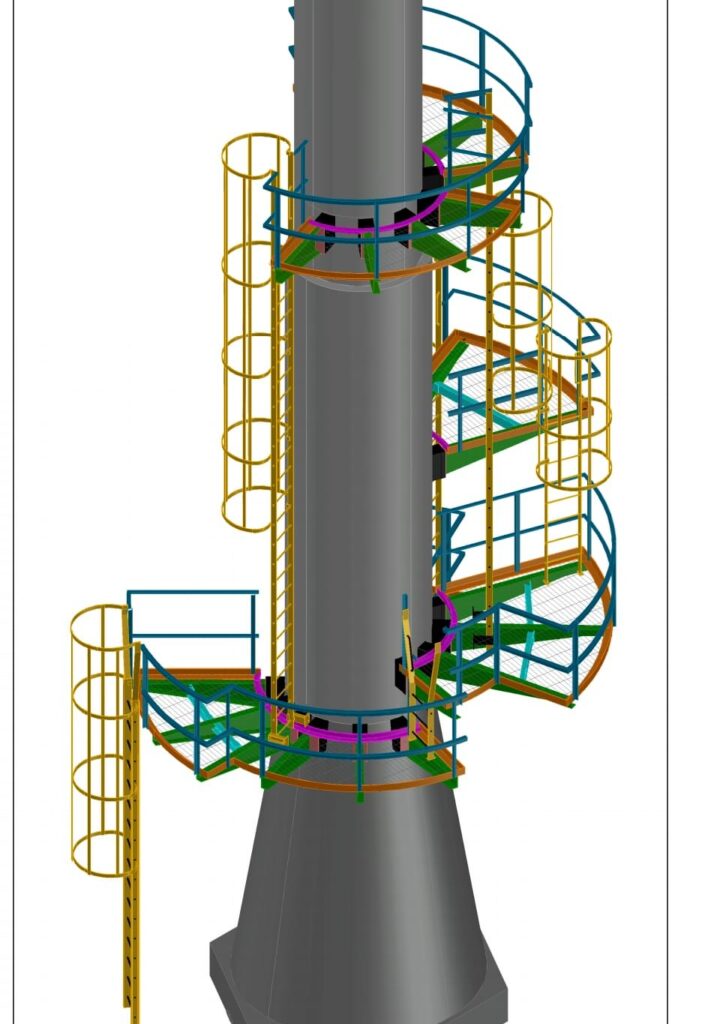

In Circular Platform & ladder Design, industrial projects involving towering infrastructures like 80-meter-high chimneys, safety, precision, and longevity are non-negotiable. Integral to such structures is the meticulously designed curved platform system paired with cage-type ladders, engineered to facilitate inspection, access, and emergency egress. The cornerstone of these assemblies lies in CAD drafting engineering consultancy, which enables robust detailing, fabrication accuracy, and streamlined execution.

Material Overview and Component Breakdown

Every structural element in Circular Platform & Ladder Design is fabricated from IS2062-grade steel, selected for its high tensile strength, weldability, and durability. These components are subjected to hot-dip galvanization, ensuring long-lasting corrosion resistance across all weather conditions and industrial exposure.

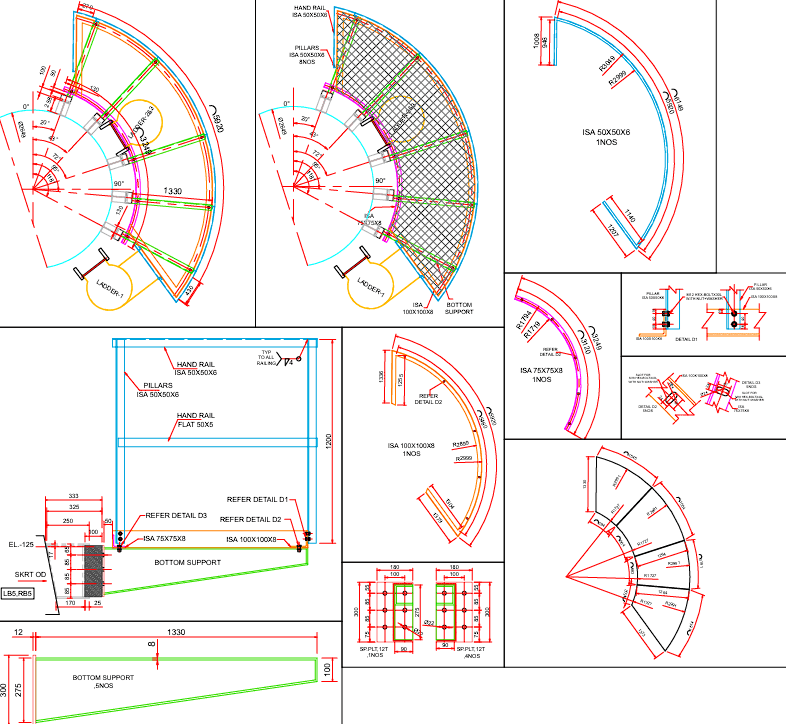

Key Circular Platform & Ladder Design elements include:

- Inner and Outer Curved Angles: These serve as the primary framing structure, conforming to the chimney’s curvature.

- Chequered Plate (Middle Part): Manufactured from IS2062 material, this anti-slip flooring ensures worker safety during all weather conditions.

- Bottom Support Brackets: These brackets anchor the platform securely to the chimney, distributing weight efficiently.

- Mounting Clits: Engineered for precision, they hold various components tightly in place, minimizing structural shifts.

- Railing Posts (50x50x6 mm Angles): Provide perimeter safety while maintaining unobtrusive visibility.

- Toe Guard Plates: Prevent accidental tool drop and foot slippage, reinforcing platform security.

CAD Drafting Engineering Consultancy: Building Accuracy from Concept to Completion

The fabrication detailing begins with intensive CAD drafting engineering consultancy, offering:

- High-fidelity 3D modeling of Circular Platform & Ladder Design geometry

- Structural detailing of chequered plates, brackets, and railing assemblies

- Platform connection details and bolt mapping

- Chimney wraparound profiles and MTO alignment

- Load calculations and wind resistance simulations

Utilizing the expertise of CAD drafting engineering consultancy, engineers develop precision drawings that are fabrication-ready, reducing margin for error and enhancing installation efficiency.

3D Fabrication Detailing with MTO Integration.

The importance of accurate Material Take-Off (MTO) cannot be overstated. It ensures:

- Optimal procurement of raw materials

- Budget alignment with design specifications

- Reduction of waste and over-purchasing

Through CAD drafting engineering consultancy, MTO reports are generated directly from design models, translating visualized data into actionable procurement logistics.

Engineering Challenges & CAD-Based Solution

Designing around an 80-meter chimney poses several complex challenges:

- Wind Load & Aerodynamics: CAD simulations via engineering consultancy help map wind flows and identify reinforcement requirements.

- Thermal Expansion Tolerance: CAD drafting predicts expansion ranges, guiding bracket spacing and joint flexibility.

- Precision Curvature Matching: With curved angles and circular geometry, CAD drafting ensures seamless integration without manual adjustments during installation.

Each challenge is overcome by applying targeted expertise in CAD drafting engineering consultancy, leading to optimized designs that perform under extreme industrial conditions.

Fabrication Efficiency & Safety Optimization.

Thanks to CAD-guided fabrication detailing, workshops produce:

- Cut-to-length chequered plates and angles

- Pre-galvanized mounting brackets and railing kits

- Bolt packs matched to MTO quantities

This digital-to-fabrication pipeline—powered by CAD drafting engineering consultancy—shortens production cycles and ensures that each component fits perfectly during on-site erection.

Why CAD Drafting Engineering Consultancy Makes a Difference

Without CAD drafting engineering consultancy, such complex structures would be nearly impossible to execute with precision. It’s the engine driving:

- Consistency across design and fabrication

- Compliance with safety codes and material standards

- Efficiency in both cost and schedule management

- Our Social Presence – LinkedIn

From initial concept to final installation, CAD drafting engineering consultancy transforms theoretical designs into structurally sound platforms that enhance industrial safety and longevity.

Why It Matter

High-quality Circular Platform & Ladder Design is not just about safety—it’s a statement of reliability and engineering excellence. The circular platforms and cage ladders allow technicians to conduct inspections, maintenance, and emergency response swiftly. The hot-dip galvanized IS2062 components ensure the platforms remain rust-free and structurally sound even after years of exposure.

More importantly, with CAD drafting engineering consultancy integrated from concept to commissioning, you not only get top-tier design but also a project that meets deadlines, budgets, and global standards.

GET IN TOUCH FOR