Designing pressure vessels is a critical task in mechanical and process engineering. These containers, which hold gases or liquids at high pressure, must be meticulously engineered to ensure safety, reliability, and compliance with international standards. In this article, we’ll explore the top essential pressure vessel design calculations that every engineer, manufacturer, and plant operator should understand. Whether you’re designing a simple air receiver or a complex chemical reactor, mastering these calculations is key to optimizing performance and preventing catastrophic failure.

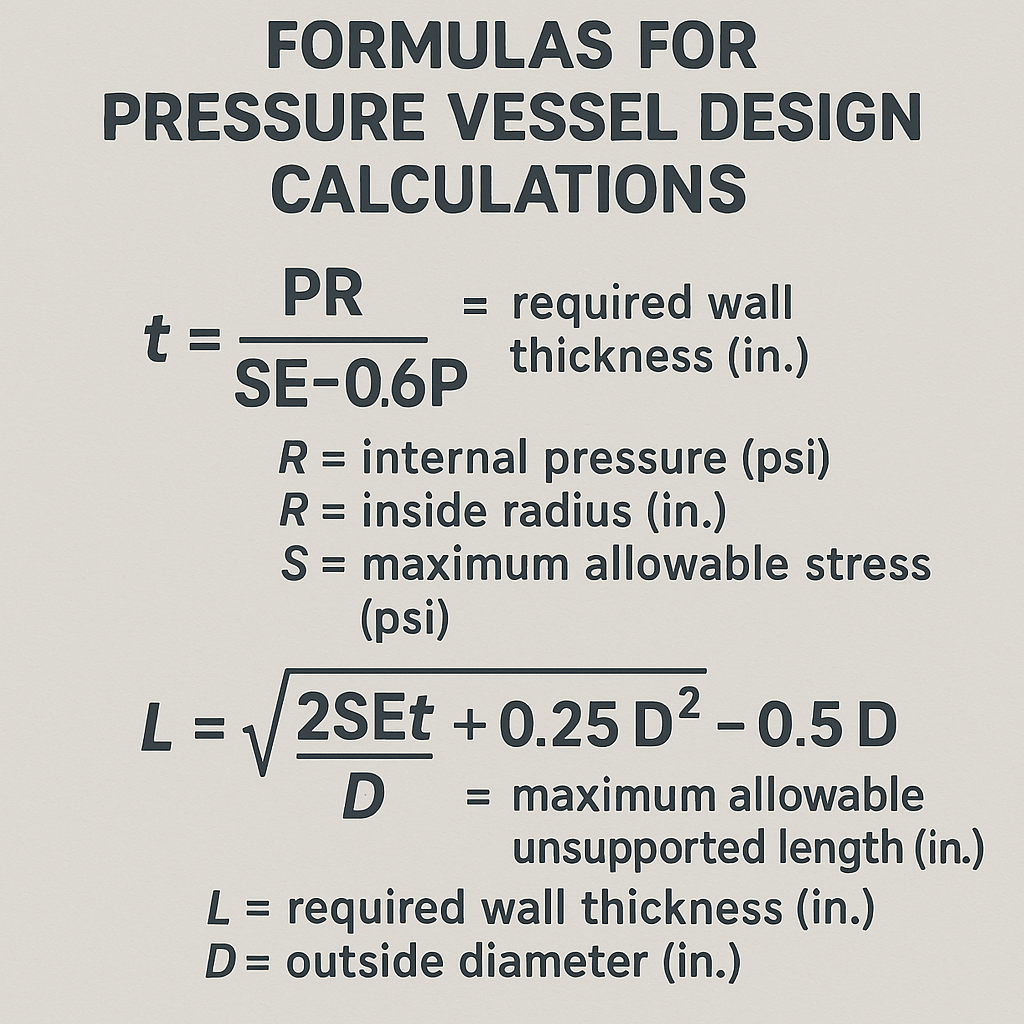

1. Internal Pressure Calculation

The first and most fundamental step in pressure vessel design is determining the internal pressure the vessel will withstand. This includes:

- Operating pressure: The pressure during normal operation.

- Design pressure: Typically, 10–15% higher than operating pressure to account for surges.

- Maximum allowable working pressure (MAWP): The highest pressure the vessel can safely handle.

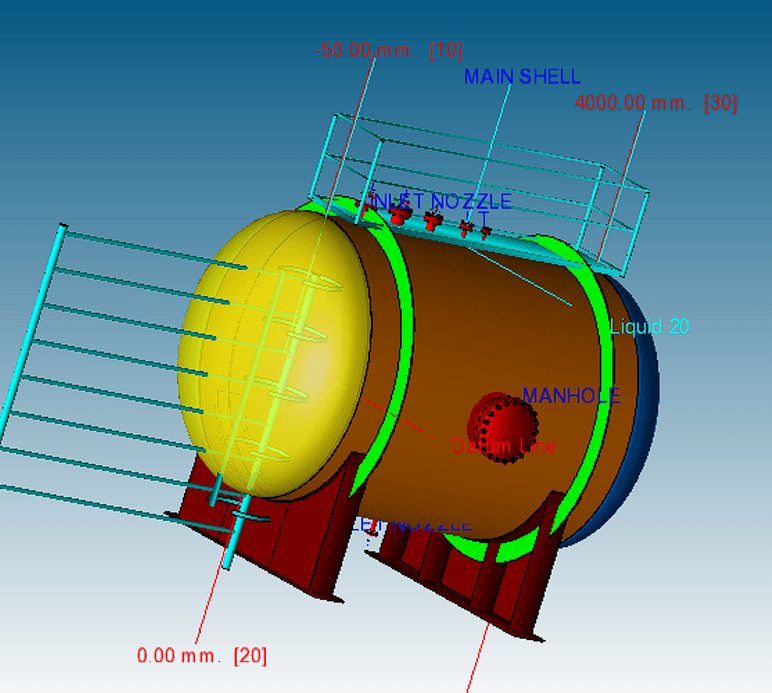

2. Head Design and Stress Analysis

Pressure vessels often have elliptical, hemispherical, or torispherical heads. Each shape affects stress distribution and fabrication cost.

- Hemispherical heads: Best stress distribution, but expensive to fabricate.

- Elliptical heads: Common compromise between performance and cost.

- Torispherical heads: Economical but higher stress concentration.

Calculation involves determining the required thickness and radius based on internal pressure and head geometry.

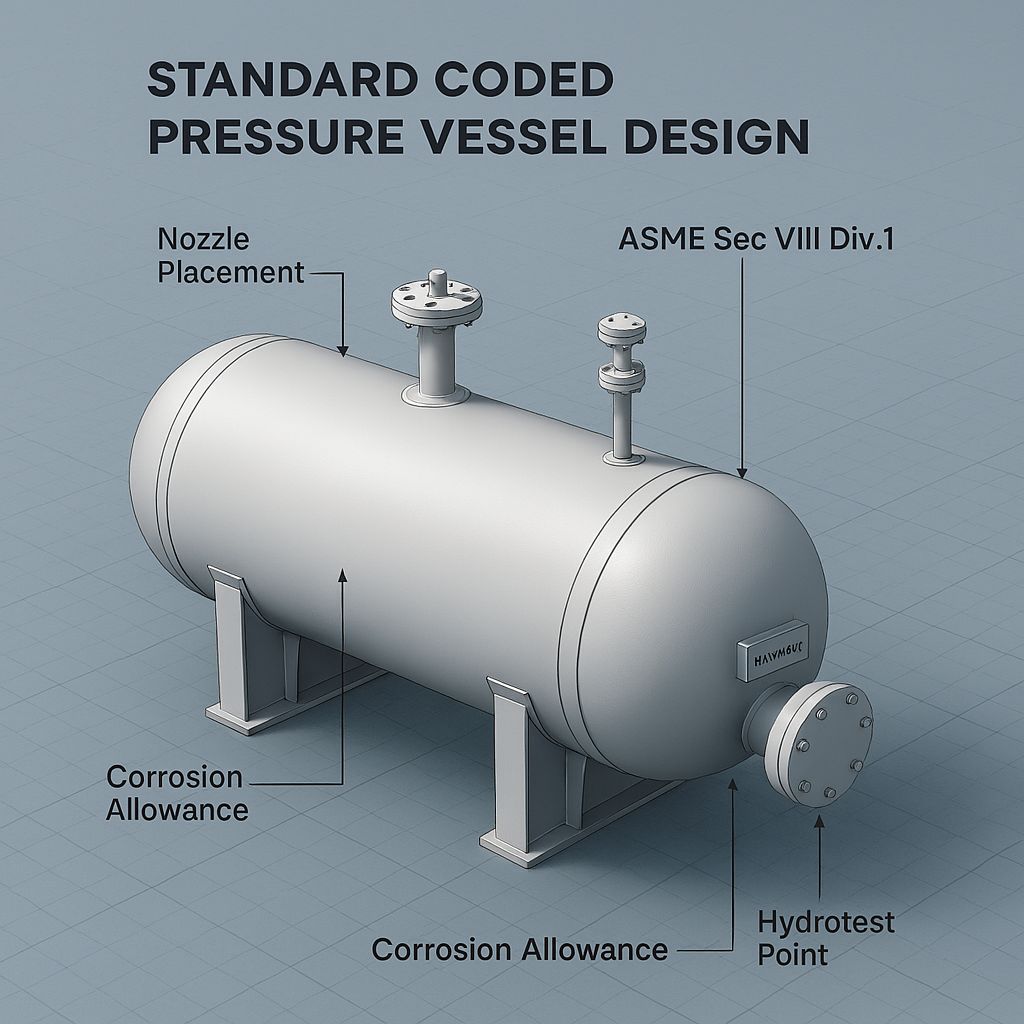

3. Nozzle and Opening Reinforcement

Nozzles, manways, and other openings weaken the vessel wall. Proper reinforcement pad design is essential to maintain structural integrity.

Design considerations:

- Area replacement method: Reinforcement must equal the area removed.

- Stress concentration factors

- Welding and inspection requirements

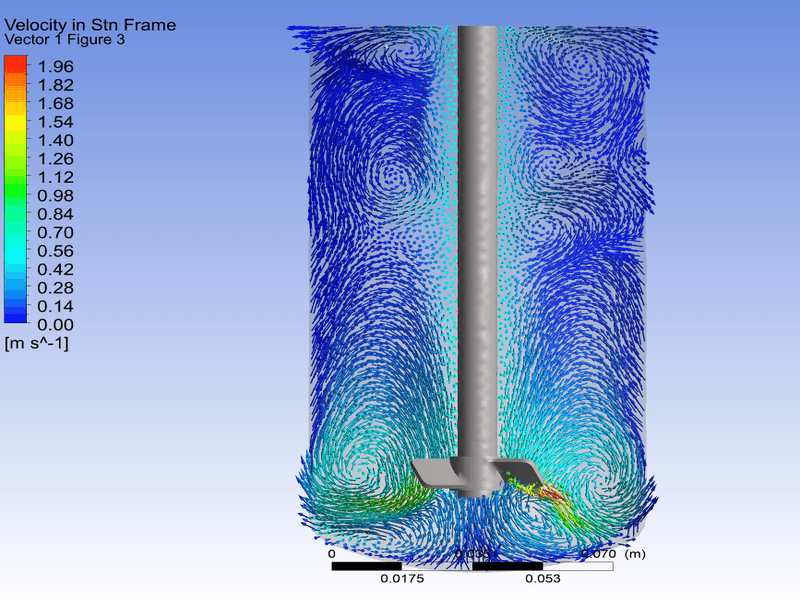

4. External Pressure and Vacuum Conditions

Vessels operating under vacuum or external pressure (e.g., jacketed vessels) require buckling analysis.

Key calculations:

- Collapse pressure

- Stiffener ring spacing

- Shell stability under external loads

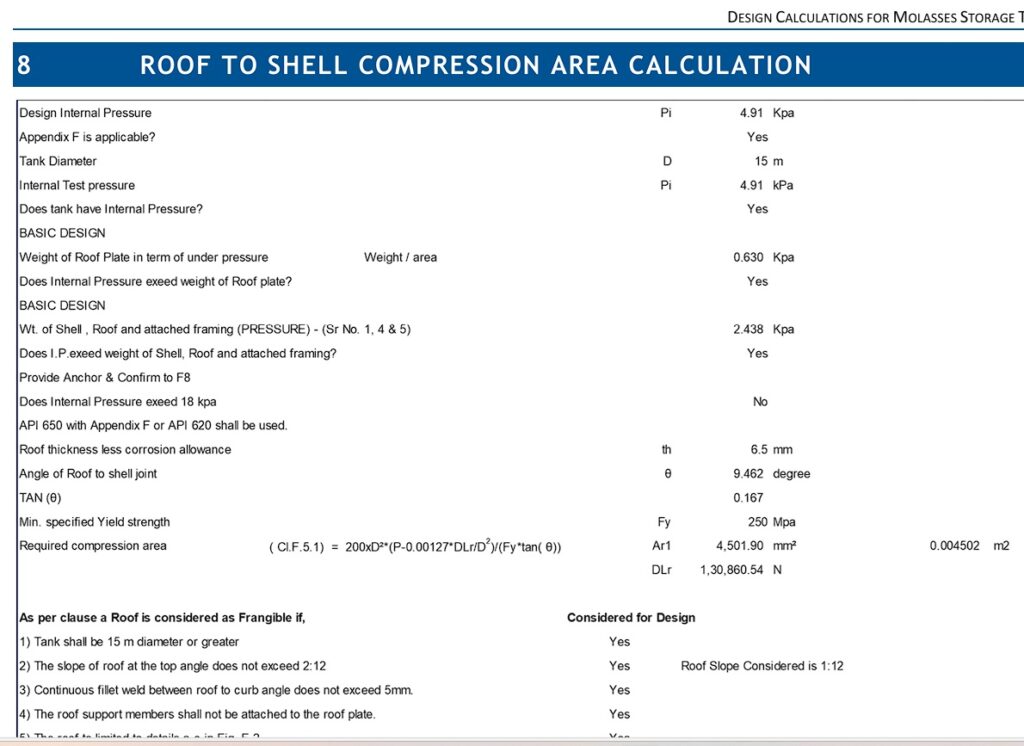

When it comes to pressure vessel design, safety, reliability, and compliance are paramount. Pressure vessels are used in a wide range of industries including oil and gas, chemical processing, power generation, pharmaceuticals, and food manufacturing. Poorly designed vessels can pose serious risks, so it’s essential to adhere to stringent codes and standards during the design and fabrication process.

This guide outlines the critical considerations for pressure vessel design, focusing on regulatory compliance, material selection, operational conditions, and safety requirements.

Importance of Pressure Vessel Design

Pressure vessel design is not just about selecting materials or dimensions; it’s a comprehensive engineering process that ensures a vessel can safely hold gases or liquids under high pressure. Proper design improves operational efficiency, reduces maintenance costs, and minimizes the risk of failure or hazardous incidents.

Key Design Considerations

1. Compliance with Codes and Standards

One of the most crucial aspects of pressure vessel design is adherence to internationally recognized codes and standards. These standards provide guidelines for material selection, design procedures, testing, inspection, and documentation.

Some of the most widely used codes and standards include:

- ASME Boiler and Pressure Vessel Code (BPVC) – Widely accepted in North America and globally, ASME Section VIII deals specifically with pressure vessel design, construction, and inspection.

- EN 13445 – A European standard that covers the unfired pressure vessels’ design and manufacture.

- PD 5500 – A UK code often used for pressure vessel design when EN 13445 is not applicable.

- API Standards – API 510 (inspection), API 650 (welded tanks), and others provide additional industry-specific guidance.

Meeting these standards ensures that pressure vessels meet safety, legal, and operational requirements in the region of use.

2. Material Selection

The choice of material plays a pivotal role in the durability and performance of the vessel. Factors such as pressure, temperature, corrosion, and the type of fluid contained must be considered.

Common materials include:

- Carbon steel – Cost-effective and widely used for standard pressure applications.

- Stainless steel – Preferred for corrosive environments.

- Alloy steels – Ideal for high-temperature or high-pressure applications.

- Non-metallic materials – Such as composites or plastics, used in specific chemical applications.

Choosing the correct material impacts not only the lifespan of the vessel but also its safety and maintenance requirements.

3. Operating Conditions

Designing for actual operating conditions is crucial. Engineers must account for:

- Internal and external pressure

- Temperature ranges

- Cyclic loading or fatigue

- Dynamic loads

- Corrosive or abrasive media

Understanding these parameters helps in selecting the appropriate wall thickness, joint configuration, and safety devices like pressure relief valves.

4. Corrosion Allowances and Protective Coatings

Corrosion is one of the leading causes of pressure vessel failure. Including a corrosion allowance during design and selecting suitable internal linings or external coatings can significantly extend the vessel’s service life.

Regular inspection schedules and predictive maintenance plans should be integrated into the design process to mitigate long-term degradation.

5. Weld Design and Inspection

Welds are critical points in any pressure vessel. The design must minimize stress concentrations and ensure weld integrity through:

- Proper joint design

- Skilled welding procedures

- Non-destructive testing (NDT)

- Post-weld heat treatment (PWHT), when applicable

6. Safety and Risk Mitigation

Every pressure vessel must incorporate safety mechanisms such as:

- Pressure relief valves

- Rupture discs

- Emergency shut-down systems

Why Choose Core Design Center for Pressure Vessel Design?

1. Grounded in Reality, Not Just Theory

Unlike firms that operate purely from CAD labs, Core Design Center is led by someone who’s been on the shop floor.

You’ve seen welders troubleshoot, watched inspectors measure dish ends, and felt the heat of real deadlines. That means your designs aren’t just compliant—they’re buildable.

Our Social Presence – LinkedIn

2. ASME-Grade Accuracy with MSME-Grade Agility

We blend rigorous validation (ASME Section VIII, Division 2) with the nimbleness MSMEs need. Whether it’s shell thickness, nozzle placement, or dish end tolerances, your specs are cross-checked with software and floor realities.

3. Visual Workflows That Empower Clients

We don’t just deliver drawings—we deliver understanding. Our annotated diagrams, carousel posts, and teachable breakdowns help fabricators, inspectors, and even first-time entrepreneurs grasp the logic behind every weld and bolt.

4. Modular Design Thinking

Our vessels aren’t one-offs. We think in scalable modules—standardized shell lengths, interchangeable flanges, and adaptable support structures.

5. Branding Meets Engineering

Only Core Design Center can turn a pressure vessel spec into a LinkedIn-ready story. We know how to wrap technical depth in philosophical irony, making even a nozzle placement feel like a moment of empowerment.

6. Floor-Tested, Founder-Led

We are not just a consultant—we are a founder who’s lived the friction. That means every design carries the DNA of someone who’s tightened bolts, chased documentation, and taught others to do the same.

Failure mode and effects analysis (FMEA) and hazard and operability studies (HAZOP) are commonly used during the design phase to identify and mitigate potential risks.

GET IN TOUCH FOR A